|

|

|

|

|

|

|

| Up to 40 manufacturing operations are necessary for a knife to receive our seal of quality. Even the slightest tolerance deviation from specification -though it might not affect the slitting result, but might lead to increased wear and dust formation -will fail our stringent quality requirements. Highly precise circular knives from steel, refined, DPM, carbide and ceramicare available for the most varied applications up to a diameter of 500 mm. Besidesour large standardproduct range, together with our worldwide customers, we develops individual knives and configurations for their respective application. The precision and quality of the multiple knife blocks are just as important as the knife itself. |  | Top knives Shapes -

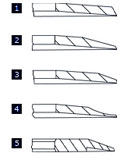

Dished simple bevel knife -

Dished double bevel knife -

Dished special bevel knife -

Dished double hollow bevel -

Flat knives in different shapes | |

|

|  |  | | Flat and dished knives | Knives for core cutting | Polished knives | Crush cutting knives | |  |  |  |  | | Mini slit knives for cutting from 05.mm | Knives for folding machines | Perforators | Knives for cardboard and slotters | | | | | | |  |  | | | | Knives for corrugated paper | Self-locking and plain bore collars | | | | | | | | | | | | | CIRCULAR BOTTOM KNIVES | | With single or double cutting edge With plain bore  or  self locking system | | | Multigroove knife blocks - Single cutting edge - Double cutting edge - In 2 pieces design - With plain bore or with screw locking - On drawing basis | | | |

|

|

|

| |